News

What are the principles and influencing factors of high temperature discoloration on the surface of 304 stainless steel pipe?

发布时间:2022-12-12 来源:荣燊不锈钢 作者:荣燊小编 阅读量:6[导读] : 不锈钢焊管表面氧化膜实际上是一种五色透明膜,其颜色变化受光干涉原理的影响。在光干涉中,颜色的出现主要是由表面氧化膜厚度的变化引起的。即当白光经过某一厚度的氧化膜,使其间某一波长的光波振荡加强,氧化膜就呈现出该波长下所对应光的色彩;当白光经过另一厚度的氧化膜,使另一波长的光振荡加强,氧化膜就显示出另一种色彩。因此,304不锈钢管的抗氧化性是解决其高温变色的有效方法。

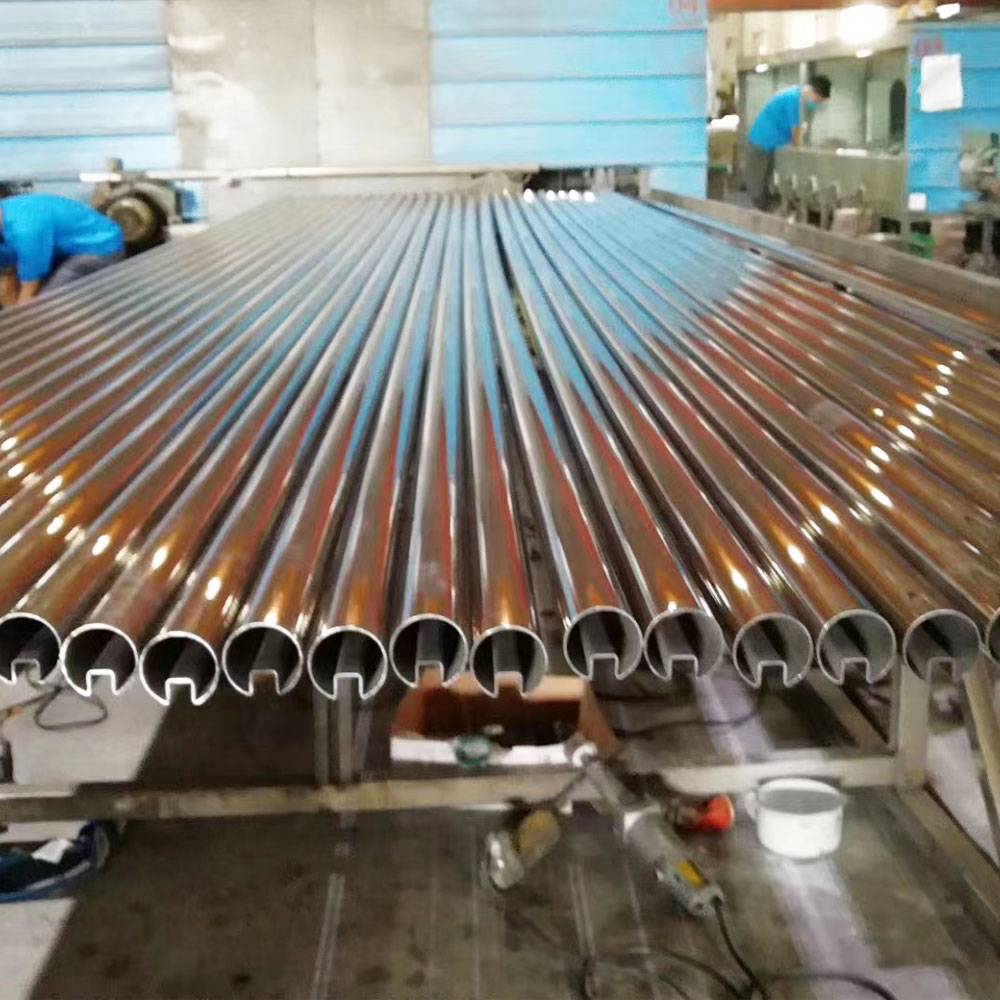

304 stainless steel pipe has good mechanical properties, corrosion resistance. As you can see from its function, it is suitable for many fields and has high temperature resistance. However, when the use temperature is higher than 450 ℃, the surface of the steel pipe will show a light yellow color. Then, what are the principle and influencing factors of high temperature discoloration of the surface of 304 stainless steel pipe?

First, the principle of high temperature discoloration of 304 stainless steel pipe

Stainless steel welded pipe surface oxide film is actually a five-color transparent film, and its color change is affected by the principle of light interference. In the light interference, the appearance of color is mainly caused by the changes in the thickness of the surface oxide film. That is, when white light passes through a certain thickness of the oxide film, so that a certain wavelength of light wave oscillation between them to strengthen, the oxide film presents the wavelength under the color of the corresponding light; when white light passes through another thickness of the oxide film, so that another wavelength of light oscillation to strengthen, the oxide film shows another kind of color. Therefore, the antioxidant property of 304 stainless steel tube is an effective way to solve its high temperature discoloration.

Second, 304 stainless steel pipe high temperature discoloration of influencing factors and solutions

The factors affecting the oxidation resistance of stainless steel are mainly chemical elements, oxide film, surface roughness.

1, chemical elements

First of all, the chemical elements, 304 stainless steel tube low carbon content, in the high temperature environment, carbon atoms in the oxidation process is easy to diffuse into the stainless steel matrix, so the oxidation process of 304 stainless steel tube is also accompanied by the carburization process. Therefore, steels with different chromium, silicon and nickel contents can be selected for high temperature cycling test. At the end of the test, the increase ratio of carbon content in various steels is measured, and the oxidation degree of the material is judged according to the amount of carburization.

In order to deeply verify the influence of silicon on the carburization resistance of stainless steel, only the proportion of silicon in 310S stainless steel is adjusted, followed by high temperature cycling test. The final test results show that the chromium element mass fraction increased to 22% above or increase the silicon element mass fraction greater than 2%, the high temperature oxidation resistance of stainless steel plate has improved significantly.

2, the influence of oxide film

Then look at the oxide film on the stainless steel plate oxidation resistance. Stainless steel plate surface of the tough oxide film can prevent the oxidant invasion of stainless steel basic, that is, to prevent the oxidation continues to produce, while the loose oxide film will make the oxide film continues to thicken. In the continuous production line to continuous pickling method of stainless steel plate surface to do forced oxidation operation, in order to enhance the stainless steel plate surface of the dense degree of oxide film.

3, surface roughness impact

304 stainless steel tube oxidation in a high temperature environment, so that the surface oxide film thickening. This situation is directly related to the material's own oxidation resistance and the material's ability to absorb heat. Surface roughness and surface color resistance will affect the heat absorption per unit area of the pipe, and affect the degree of discoloration.

Practice shows that when the surface roughness of the thin-walled stainless steel pipe is less than 0.022μm or less, its heat absorption capacity is significantly reduced, the steel pipe will not be further oxidized, the thickness of the oxide film is basically unchanged in high temperature environments, and the degree of discoloration is also very slight.

阿里巴巴店铺

阿里巴巴店铺